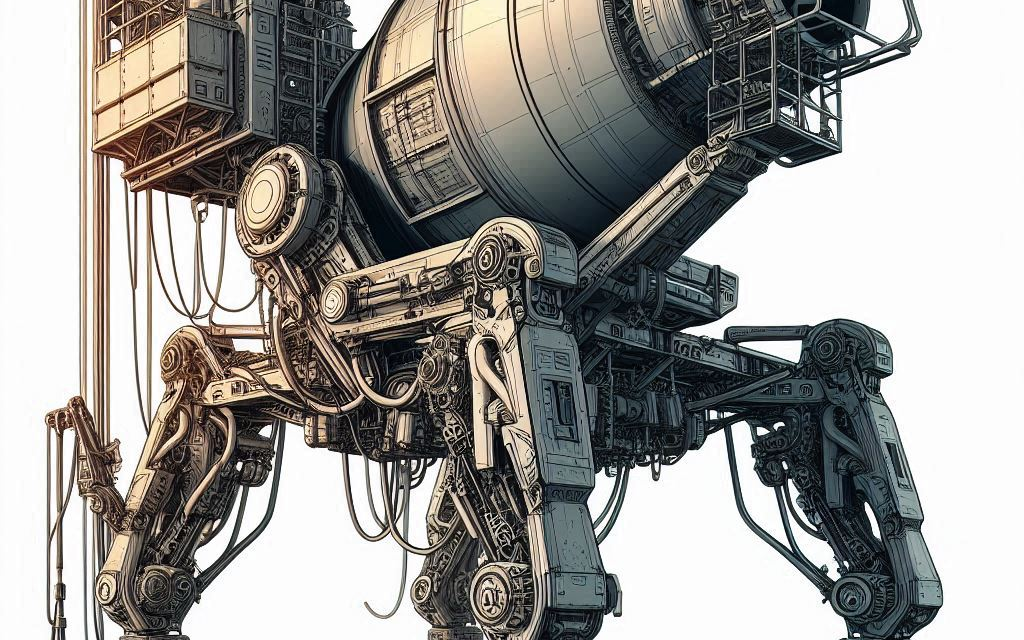

The Ultimate Guide to Concrete Mixer Machine

Concrete Mixer Machine – Construction work like that of a fine laid walls for rectifying the crime or even buildings one needed to have solid mixer machines as it is impossible without having them. The availability of these machines means that concrete can be mixed quickly and easily, providing the best possible foundations for buildings as well as work on roads. This blog will guide you to different types of concrete mixer machines, what actually the type of mixing is and also help you with tips on how certain batch sizes (Cubic feet) work during construction jobs.

How Concrete Mixer Work?

What Are the Concrete Mixer Machines? These mixers make sure that the mixture is uniform and of correct consistency as well as composition, which is key to ensuring the desired durability, intensity among others ultimately in protecting it.

Concrete Mixer Machine Types

1. Batch Mixers:

BATCH MIXERS: as the name suggests, these types of portable mixers are designed for providing concrete in large quantities (or batch). Ideal for jobs that require more concrete compared to on hand at a time and where various types of concrete need be use from one state to another. These can be classified into two major types of batches mixers.

Drum Mixers:

The type of mixer is determined by the various methods in which they rotate, and drum mixers generally contain a rotating device along with such mechanisms as paddles that help to meet requirements for rotations. There are two subtypes:

Tilting drum mixers: The capacity of the mixer is about 200 litres and concrete occupies half this volume. This makes them perfect for small jobs and also are portable in nature than can be moved from one site to another.

Non-Tilting Drum Mixers- The drum does not move, and the concrete is discharged through a chute. As with River sand, we use another popular mixing method on the market called Pan Mixer or Vertical Shaft Mixers.

1. Pan Mixers:

In pan mixers, the mixing takes place in a stationary cylindrical pan. Rotating blades of paddles provide the mixing action. The intensive action of a pan mixer makes it suitable for producing the very homogeneous mixes required in concrete, such as those used with commercial wet-cast production.

2. Continuous Mixers:

Unlike batching production, continuous mixers make concrete one after another. Perfect for large projects that require a constant supply of concrete These mixers can be either:

a. Drum Mixers:

Continuous-flow concrete pumps with the presence of some other components, like production of a continuous flow Establishing Pompes Most drum processors. processors

b. Twin Shaft Mixers:

Wire leads to a driveway Wet batch mixers have two horizontal shafts, with arms on the same side of the bed designed for pugging while also rotating by means of reverse objectives. They are famous for their huge productivity and immediate mass production of concrete.

3. Self-Loading Mixers:

Self-loading mixers are essentially a concrete mixer and mobile unit in one. This involves loading raw materials, mixing concrete together and then transporting it to the jobsite. These portable mixers are very flexible and can be used on the ground or in small batch plants where it is not possible to separate loaders from mixer.

How the Concrete Mixer Machines are put to use

And Cover Following Types of Construction Projects with Concrete mixer machines

1. Building Foundations:

The concrete mixers are the most important equipment responsible for providing strong and sturdy bases to residential as well as commercial & industrial buildings. One of the most important aspects when constructing a building is exactly how good and mixed pretty much concrete quality.

2. Road Construction:

Mixers can produce concrete for roads, bridges and other infrastructure projects. Road uniformity and the consistent mix result in a long life for this road surface.

3. Precast Concrete Production:

Concrete mixers in precast production process are used to make various products like beams, columns and panels. Batch mixers work with such precision that they are perfectly suited to the manufacture of excellent precast parts.

4. Landscaping and Hardscaping:

Concrete pathways, patios and retaining walls are all created using a concrete mixer. The mixes can be customized in order to meet the specific needs of a project.

5. Industrial Applications:

Mixers are used in the making of concrete pipes, blocks & many other industrial products. Mix consistency and, the quality make a difference to ensure that it meets industry requirements.

Advantages Of Concrete Mixer Machines

1. Efficiency:

Concrete mixers are in no time and labor saving compared to mixing concrete manually. A direct result of these capabilities and higher order language abstraction is cost savings which in-turn assists to complete the project at a faster pace.

2. Consistency:

Mixers guarantee a homogeneous and homogenized mixture, essential for the stability of the finishing product. This may result in variability and low points throughout the concrete due to mixing by hand.

3. Quality:

Henceforth, if it is used by a concrete mixer machine then the mix will be of proper proportions to cement, aggregates and water due to which efficiency ends up with better quality. It is especially crucial for structural applications.

4. Versatility:

Ranging from small residential projects to very large industrial constructions, concrete mixers work with the same degree of proficiency. This highlights that there are two general types of mixers in this list, each serving different needs, increasing their usefulness.

5. Portability:

A lot of concrete mixers are portable, so you can easily transport them to different areas on the job site. This is especially handy if you work on projects that have multiple locations or remote sites.

Buying the right concrete mixer machine

1. Project Size:

Simply take your project size and scale into consideration. A portable batch mixer is suitable for small to medium amounts. Large projects may require continuous mixers or self-loading mixers.

2. Type of Mix:

Type of Concrete Mix Needed The first step you need to take in making sure that the amount of concrete being ordered is enough for your project, early on. Certain mixers are best for certain mixes (read – high-strength concrete or precast components).

3. Capacity:

Select a mixer that can scale to your required capacity. A bigger capacity mixer can produce more concrete in lesser time; hence, provides better productivity.

4. Power Source:

Check out the source where you have power availability to use on your job site. Concerning cement mixers, power sources can be either electricity or gasoline types. It is very important to make sure that the power source corresponds with mixer.

5. Portability:

Choose portable models if you are frequently required to move the mixer around for your projects. This is why self-loading mixers are perfect for sites that require on the go mixing such as in a back woods’ village

6. Budget:

Decide on your budget and then get the best mixer you can for that price. A top-notch mixer it is hopeful that you will reduce the costs of maintenance and even daily operation.

Safe Measures For Employing Concrete Mixer Machines

1. Read the Manual:

Always refer to the manufacturer’s manual and adhere to recommendations for use and maintenance of your mixer.

2. Wear Protective Gear:

Personal protective equipment (PPE) must be used including safety glasses, gloves and ear protection when the mixer is in operation.

3. Inspect Regularly:

This prevents potential leaks, damages and a worn-out boiler. Act quickly to resolve any problems before they lead to accidents in the future or decrease your snowblower performance.

4. Use Proper Mixing Techniques:

The order the ingredients should be added into and in which ratios as well. A mixer can fail to be mixed properly, or worse yet a broken machine if the load is overloaded.

5. Clean Thoroughly:

One more thing to remember is the need for thorough cleaning after every use, otherwise concrete will harden on the machine. Every day clean-up would assist prolong the lifespan of your mixer and ensure it is consistently operation.

Conclusion

In the world of infrastructure and construction, concrete mixer machines are considered as a must-have tool for better efficiency, quality of work and consistency in concrete making. Knowing more about the various types of mixers and what they are used for allows you to select the best equipment that matches your projects, works better & enables timely completion. To get the most from your concrete mixer, along with promoting service life and sturdiness to contracts there are several guidelines used for safety purposes in order that no accidents or complications arise.

![compressor machine: Types, Uses & Benefits [Ultimate Guide]](https://techyhealthcare.com/wp-content/uploads/2024/07/Designer-2024-07-10T163722.062-440x264.png)