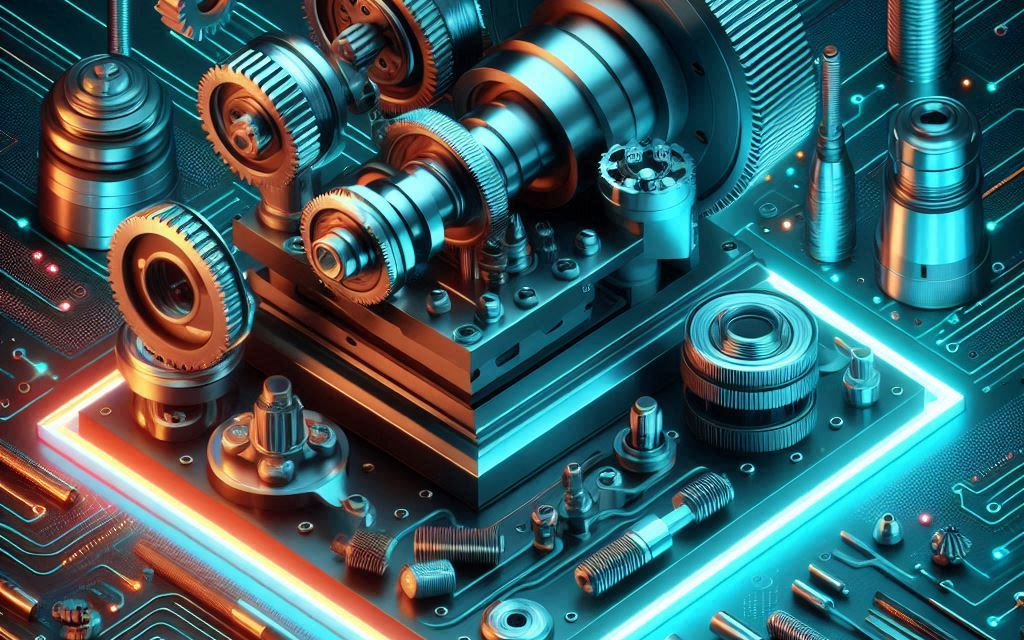

lathe machine parts, a quintessential tool in manufacturing and metalworking industries is prominently known for its aptness to accurately cut and shape the materials. A lathe machine is made up of specific parts to enable its full functionality so you must also know the different functions. In this blog, you will go through the critical elements of a lathe machine and how they affect your machining process.

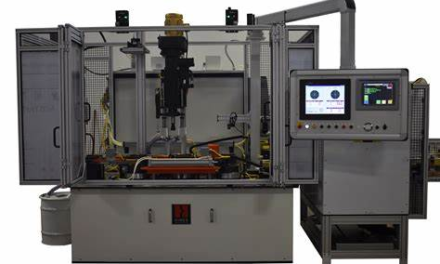

Lathe Machines in Brief

A lathe machine is a multipurpose piece of equipment that can be used to perform drilling, cutting, knurling and turning. It is classified as a turning process, where the workpiece shapes by rotating it around a fixed cutting tool. Lathes are designed for processing shafts, cutting threads and complex surface operations.

Key Parts of a Lathe Machine

1. Bed

Bed is the backbone of lathe machine and basically it provides a strong foundation for all other parts. To keep the headstock, tailstock and carriage in place during operations The bed is usually made of cast iron for its vibration-damping and heat-control properties.

2. Headstock

The headstock is mounted on the left end of bed and houses main spindle, speed change mechanism and feed change gearbox. With its possibility of using the main spindle (which is an indispensable component because it carries and turns the work piece), Within the headstock are gears and pulleys which control various speeds of spindle allowing different cutting speeds and torque selections.

Headstock Key Components:-

Main Spindle: The workpiece is held and rotated by the main spindle.

Speed/duty control – changes the rotation speed of a spindle, adapting it to work at different materials.

Chuck : It is a clamping device that fastens the workpiece to spindle tightly.

3. Tailstock

The tailstock sits on the far-right side of the bed and helps support the workpiece, particularly during long or slender machining processes. It can slide on the bed and be locked in place. A tailstock holds tools such as drills or reamers and can be moved along the bed to align with the spindle.

Functions of the tailstock

Support – Adds support to the workpiece and prevents it from deflecting.

Tool Holding: To hold the digging, ripping or drilling machine.

Adjustability-Can be re-locatable and locked in operations.

4. Carriage

The carriage (not shown) is another important part of this machine that holds and moves the cutting tools. It travels over the bed to execute different machining operations either by manual or automatic control. The carriage is composed of several parts, each havingits own role to play:

Contents of Package: Key Components

Saddle: The large platform of the carriage that moves along the bed itself.

Cross Slide – The cross slide is located on the saddle then moving up and down but perpendicular to workpiece axis.

Tool Posts: Box Type/ 4 way, Turret type Compound Rest : Supported on cross slide,provides for angular setting of tool

Tool Post: Used to clamp and hold the cutting tools in position for rapid exchange.

5. Apron

Apron Apron is mounted on the face of carriage in which all movements are performs like Carriage and cross slide It contains an appliance for control of experimental equipment, gears and clutches etc. both the longitudinal motion as well circular feeds

Key Functions of the Apron:

Feed Control: It controls the displacement of carriage and cross slide.

Control levers (engage, disengages) the threading and feeds.

6. Lead Screw and Feed Rod

The lead screw and feed rod provide for automatic movement of the carriage. Thread-cutting operations make use of the lead screw, and for general turning work the feed rod is used.

Key Functions:

Lead Screw – Enables Accurate Lathe Threading in Longitudinal Movement.

Feed Rod: Provides a consistent feed rate for turning operations

7. Chuck

A chuck is a clamping attachment which clips into the headstock spindle. It securely holds the workpiece while machining. Chucks can also be broken down into subcategories such as the three-jaw and four-jaw style chuck which are used in different applications.

Types of Chucks:

Three-jaw chuck; self-centering, most commonly used for round work pieces.

Four-Jaw Chuck: Individual adjustable jaws, ideal for odd, shaped workpieces.

8. Tool Post

Holds the cutting tools in a tool post mounted on compound rest. Necessary for rapid tool changes and hence efficient machining operations. The quick-change tool post is one kind of many other types, and it allows fast-disconnect tooling without lost change in tool’s position.

Key Functions:

The tool holding: Holds the cutting tools.

Precision: You can get the tools exactly where they should be.

9. Steady Rest and Follower Rest

These are supporting tools that prevent long, slender workpieces from deflecting or vibrating. Steady rest bolts down to the bed, supports workpiece Follower steady moves with carriage.

Key Functions:

A steady Rest: It is used to support the workpiece while machining.

Follower rest-follows along with the carriage and provides continuous support.

10. Chip Pan

The Chip Pan sits at the bottom of the lathe machine, collecting all metal chips that come off during machining. This enables you to keep your work area clean and prevents chips from building up causing the mill not function properly.

Key Functions:

Chip Collection – Gathers metal debris and chips.

Cleanliness: it maintains the neat working place.

Conclusion

Anyone involved in machining or manufacturing can benefit from a knowledge of the different parts of a lathe machine. All make up a specific part, and have their own function in the workings of the machine as they contribute to its operation functionality & accuracy. Whether you are a machinist, an engineer or just someone who owns one of those machines at home – having good understanding about lathe machine parts would empower you to operate it better when the need arisesOTLimachinery is so that with OTLinkdevoting its intrinsic meaning in future requires both visualization and forming qualifications.

Know all these functions and components to enhance your workpiece, increase productivity as well as mass production quality on the result of machining. A lathe machine that is clean and well-kept can always give you more accurate cuts, whether you are using it to cut wood or metal.