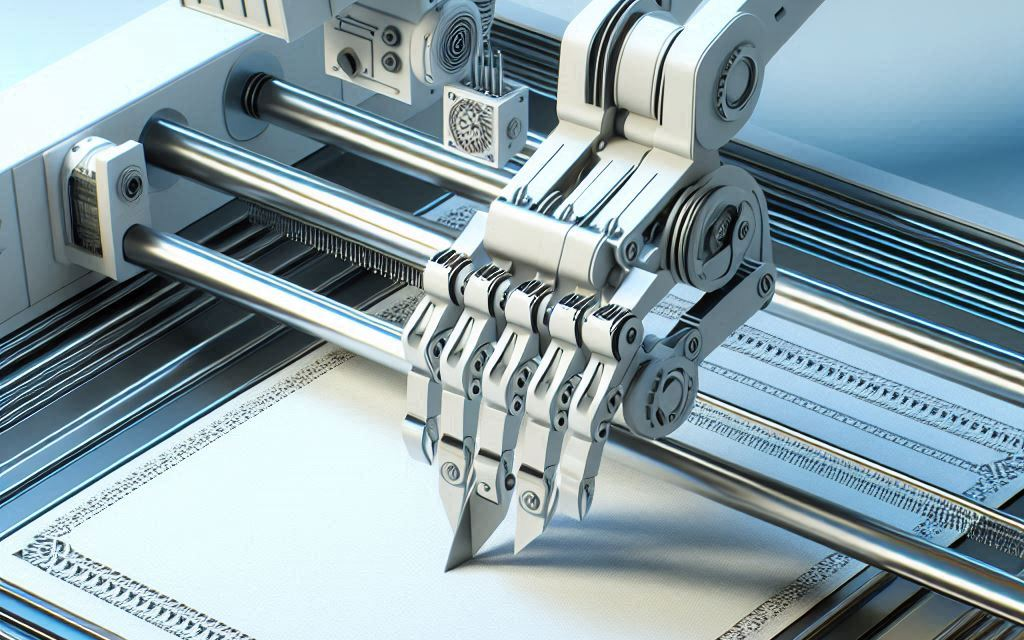

paper cutting machine – The usage of a paper cutting machine is present in many fields including printing, packaging and craft industries along with the offices. These machines deliver accuracy, productivity and overall functional for every job when it comes to cutting paper in different sizes and designs. This article explores how to use a paper cutter, the best models available are along with tips on choosing one for your Specific.

Paper Cutting Machines Overview

What is a Paper Cutting machine (Paper Cutter / Guillotine)? The machines range from small desktop manual units to big automated industrial equipment. Ultimately, the goal of a paper cutting machine is to deliver smooth and crisp cuts as efficiently and quickly as possible.

Paper Cutting Machines Types

1. Manual Paper Cutters

Manual-Based: These are paper cutters that an individual operates by hand and which have low-to-medium capacity cutting thanks to their size. Great for personal or small office use These cutters tend to have a mechanical lever or rotary blade in which the user physically activates it to slice through the paper sheets.

Advantages:

Affordable and easy to use.

Best For: Light to Intermediate cutting.

Can unplug and move to take anywhere.

Disadvantages:

Reduced cutting depth than electric saws

How hard/easy is it to move from here to there in the interface?

2. Electric Paper Cutters

Electric Paper Cutters: These are powered by electricity and are suitable for large volume cutting jobs. These machines allow for a higher degree of accuracy and productivity, which makes them ideal for commercial or industrial purposes. These will often have a motorised blade and options to select an exact cut, resize Mode

Advantages:

Fast and capable of high cutting volumes.

More precision and settings are programmable.

For the user less physical exertion.

Disadvantages:

Much costlier than their manual counterparts.

Needs power input and maintenance.

3. Hydraulic Paper Cutters

Further, as the name suggests hydraulic paper cutters are integrated with hydraulic systems for creating cutting force so that it can easily cope up large stacks of papers. They are widely employed in high volume, industrial applications and need to be heavy duty processes.

Advantages:

Razer sharp cutting power and capability.

High accuracy with variable reusability

For large scale industrial use

Disadvantages:

Very expensive and high maintenance.

Needs its own power and space

4. Rotary Paper Cutters

A rotary paper cutter is perfect for creating straight, precise lines with its circular blade that rolls along a fixed track. They are often used to cut a single sheet or insert papers by hand. Craft or design oriented useThis cutter is a favorite of crafting and designing applications.

Advantages:

Ideal for small quantity precision cuts in single sheets or a low portion of pages.

Easy to use and control.

Best for precision, fiddly cuts

Disadvantages:

Limited cutting capacity.

Not For High Volume Operations

Key Features to Consider

When selecting a paper cutting machine, there are some features that you need to put in mind so as the cutter may satisfy your requirement:

1. Cutting Capacity

We know what the cutting capacity means- this is the number of sheets at once, a machine can be separate. This is a major consideration depending on the cutting tasks that you anticipate performing. While manual cutters have capacities at the lower end of the scale, electric and hydraulic designs are capable of cutting through larger stacks.

2. Blade Quality

Clean and accurate cuts are only achievable with the right blade that is of utmost quality and sharpness. Find machines with replaceable/sharp-able high-quality blades.

3. Cutting Precision

Both of those things are important–hey, nobody said this was going to be easy–especially for stuff that requires clean and consistent cuts. Programmable settings: Electric or hydraulic cutters might allow for more programmability to tighten things up. On the other hand, manual and rotary paper cutters are usually driven by you seeking a better grip manually.

4. Safety Features

Safety first with cutting machines. Seek models equipped with safety blade guards, locks and automatic shut-off systems to avoid accidents or injuries.

5. Ease of Use

This is especially true if the machine will be used frequently or by more than one person. Intuitive controls, easy blade changes and accurate measurement guides will go a long way to make it easier to use.

If you would like to know more about why paper cutters are ruled out universal tools in the market.

1. Time Efficiency

Paper cutting machines save us an immense amount of time especially when you are dealing with large piles. This improved efficiency is expected to raise productivity in office, printing and crafting spaces.

2. Consistency and Precision

Such machines make sure that the cuts are all same and at one place each time coming out of it. This is an automatic process that should be done, especially in the daily work to keep as it was born uniformity for example: printing and packaging.

3. Versatility

Paper cutting machines can work with many media types such as paper, cardstock, fabric and more. As a result, they are applicable for crafting and industrial manufacturing alike.

4. Reduced Waste

The right cut avoids waste by allowing the materials to be used in an optimum manner. Not only does this save money, but it is also good for the environment.

Points to be keep in mind while Choosing Paper Cutting Machine

1. Assess Your Needs

Think about how often you are going to cut and what kind of it. A manual or rotary cutter may be more than adequate for occasional use, small projects. Employ an electric or hydraulic cutter for high-volume manufacturing duties, industrial purposes.

2. Evaluate Space and Budget

How much space do you have and is there room in your budget? While manual cutters are smaller and less expensive, electric or hydraulic models take up more room as well a cost.

3. Read Reviews and Get Feedback

Look at several machine models, as well as feedback from other users on their performance and the quality of cleaning they can achieve. Some are more reliable than others and this can serve as a check on your analysis.

4. Consider Future Needs

Consider What You Will Need in the Future and Whether the Machine Can Handle it. If you expect to have higher demand or more challenging cutting jobs, purchasing a somewhat better-quality model could be worth it for your business.

Conclusion

For anyone doing regular paper or other sheet materials the most useful tool you cannot be seriously without a doubt yes, it has been no less than 25 years because the Dahle first came out. dB Dawson web internet. Whether you are in a busy print shop, office setting or creative studio the correct paper cutting machine can improve your efficiency, precision and ultimately productivity. Knowing the cutters that comprise a waterjet system, and for what each type is best suited. A good quality paper cutting machine will be a time and labour saver that helps to ensure your projects are completed with precision ensuring you provide the best finished product in terms of accuracy, speed or professional standard.

![compressor machine: Types, Uses & Benefits [Ultimate Guide]](https://techyhealthcare.com/wp-content/uploads/2024/07/Designer-2024-07-10T163722.062-440x264.png)