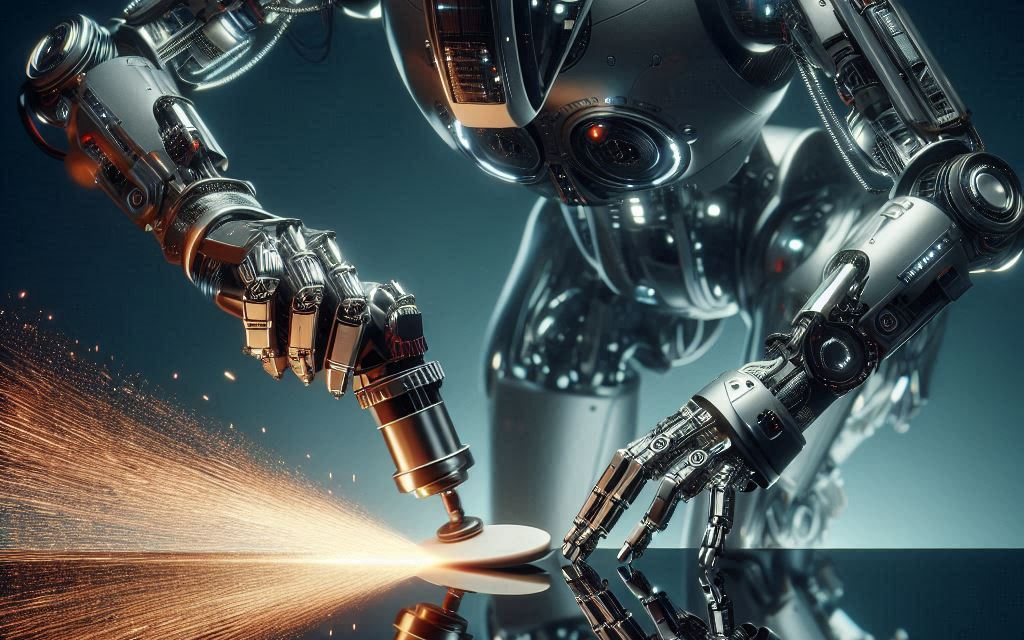

Optical Mirror Polishing Robot – At the top of innovation, technology has presented us with optical mirror polishing robots that provide unmatched precision and quality in creating high-quality optical mirrors. These advanced robots are suited for the demanding tolerances found in fields like astronomy, microscopy, telecommunications and laser technology. In this article, we will discuss deep about the technology used for optical mirror polishing robots, where they are useful in what type of applications and some benefits with future possibilities.

The Role Of Optical Mirror Polishing

Optical mirrors are an essential component in high-precision applications. The performance of these optical systems is directly related to the quality precision mirrored surface. The perfect finish surface reflects light better and minimizes the scatter of this. The polishing of optical mirrors in a manual process that is performed by trained craftsmen, making it highly labor intensive and error-prone. Fully automated optical mirror polishing robots solve this problem by executing the process with a level of precision unmatched.

Manual and Automatic System of Optical Mirror Polishing Robots

As per Advanced Photon Source (): Optical mirror polishing robots are state-of-the-art systems that use modern technology to achieve the high precision necessary for processing optical surfaces. Following is a deep dive into these essential ingredients and what they do:

1. High-Precision Robotic Arm

A key part of the polishing robot is its robotic arm, which enables it to navigate around complex mirror surfaces thanks to a range of dexterity and motion. The arms are usually powered by high-precision servo motors so that they move from one end to the other with a lot of ease along multiple axes.

2. Specialized Polishing Tools

Its end effector or polishing tool is designed for optical polishing specifically. The tool also consists of diamond abrasive pads together with polishing compounds which are coupled to the custom deigned polish heads that provide the necessary pressure and motion as needed for achieving an optical surface finish. The selection of polishing tool varies with the material and precision of mirror to be polished.

3. Real-time Feedback and Control Systems

To maintain accuracy during the polishing process, advanced sensors and feedback systems are essential. These sensors also measure force, position as well as surface roughness during the operation. Sophisticated control software processes the feedback and dynamically adjusts the robot’s actions to make them more repeatable, while reducing the potential forover-polishing or damage.

4. Adaptive Software Algorithms

It is the control software for optical mirror polishing robot. Employing adaptive algorithms and artificial intelligence (AI) for polishing, including a look-ahead feature. These algorithms, based on real-time sensor data, tune themselves continuously to optimizing for performance as well as accuracy. The software also improves with each cycle of polishing, as it learns over time.

Optical Mirror Polishing Robots Applications

High-precision optical mirror polishing robots are used in industries where high-quality mirrors have a must. Relevant applications are as follows:

1. Top Picks Astronomy Space Exploration

Large optical mirrors are used in astronomy, particularly as telescopes to collect and concentrate light from very distant extraterrestrial objects. Getting these mirrors polished to near-perfection is essential for sharp, detailed imaging. Optical mirror polishing robots, for example, have been used to polish large mirrors (used in ground-based observatories and space telescopes) with the requisite precision.

2. Microscopy

Optical mirrors in microscopes are used to reflect and focus light onto samples. Even minor defects in the mirrors can disrupt images and lower a microscope’s resolution. Polishing robots that create ultra-smooth mirror surfaces in microscopes support high-precision and reliable scientific observations.

3. Laser Technology

In laser systems, optical mirrors are an essential component which reflect and collimate the beam in a way as to minimize loss of energy. High precision in the mirror surfaces is necessary to preserve beam quality as well as efficiency. This is where polishing robots come in and deliver the pristine finishes needed for mirrors that will be equipped onto medical lasers or as part of industrial cutting systems, while also matching scientific research milestone.

4. Telecommunications

Optical mirrors are widely used in telecommunications to tailor light signal handling and promote optimum system performance. Quality mirrors are necessary for reducing signal loss and transmitting the data efficiently. Robots are employed to further refine the output, by doing so allow for fabricating perfect mirrors that would generate a high quality of fiber optic communications and other telecommunication technologies.

5. Optical Instruments

High-precision mirrors are necessary in optical instruments such as cameras, binoculars and spectrometers. Robots then polish these mirrors, so they are made to a high degree of precision prior to be being used for optical observation.

Advantages of Optical Mirror Polishing Robots

Optical Mirror Polishing Robots Benefits – Transforming Optical Mirrors into Production

1. Unrivaled precision & consistency

Optical mirror polishing robots provide a consistency and accuracy that manual polishes are unable to attain. The end result are high-quality mirrors with fewest surface defects, a must-have for good optical performance.

2. But it will skyrocket your efficiency and productivity.

Robots automate a major part of the polishing process; this results in faster and efficient completion. No of. ROBOTS Robots can work non-stop without tiredness, making the polishing time for each mirror shorter and so enhancing Overall TP..

3. Cost Savings

Although the outlay for optical mirror polishing robots can be costly, significant long-term costs are saved. This help companies to cut labor cost, waste less material and produce it in an efficient way so that you can have your ROI.

4. Improved Safety and Ergonomics

Polishing work, in general, is a kind of task that contains repetitive human motion, and workers are prone to different kinds of hazards (like hazardous chemicals). Optical mirror polishing robot remove these risks by relieving the operators of demanding and dangerous work, it also creates a safer environment.

5. Flexibility and Adaptability

Optical mirror Werk Raum robot capabilities are in high-precision manufacturing and numerous tasks with diverse materials. This versatility makes them ideal for a range of applications, and helps manufacturers accommodate fast changing production requirements.

Future Perspective and Innovation

Competing against advances in other fields, such as robotics, AI and materials science among others the potential upliftment of capabilities for optical mirror polishing robots could be quite promising in future.

1. AI and Machine Learning revamped

And in the future, when AI and machine learning continue to advance, optical mirror polishing robots will be smarter and more autonomous. This allows the robot to learn from previous polishing cycles and gain optimal knowledge therefore with minimal or no human intervention, adopt new tasks.

2. Integration with Industry 4.0

Industry 4.0 technologies, the digital twin and the IoT will allow optical mirror polishing robots to be integrated for better monitoring and control of the mirror-polishing process as well Which will make a way for smarter process optimization,predictive maintenance and Data driven approach.

3. New Coatings and Advanced Materials

Newer materials and coatings will also enable robots to polish optical mirrors more than previously possible. For example, new abrasives and polishing compounds can improve the capabilities of a polish process itself so that robotic systems are capable to reach even further levels in surface finish.

4. Collaborative Robots (Cobots)

Similarly, the production of optical mirror polishing robots may fall within reach for smaller manufacturers and businesses as collaborative robotic systems – abbreviated cobots – become more popular. The cobots are designed to collaborate with humans by combining the best of what both do offer, in order for them to deliver optimum results without any dangers.

5. Sustainability and Environmentally-Friendly Practices

Sustainability will also be an area of innovation in optical mirror polishing robots being developed for the future. We are working to create an environmentally friendly polishing material, energy-saving robots and processes that seek minimal wastage which benefit the environment.

Conclusion

Robotic optical mirror polishing is both a revolutionary and advanced field of optics, delivering numerous advantages that disrupt conventional methods for the better. Arguably even more impressive, the robots not only are providing consistent high-quality finishes but they also improve efficiency and increases safety while maintaining competitive costs to many industries dependent on pristine optical surfaces. And as technology marches on, the reach of optical mirror polishing robots can only grow and develop to allow for even greater innovation and opportunity. Optical mirror polishing robots; recognised across astronomy, microscopy, laser technology and telecommunications as the benchmark of optical mirror excellence.