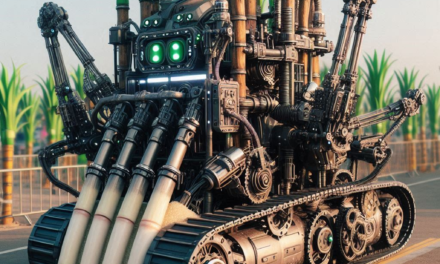

Insulation Blowing Machines- It is insulation that determines the energy efficiency of residential, commercial and industrial buildings as well as comfort. If your insulation is done properly, it will help you to maintain the temperature, save energy costs and provide complete comfort. The insulation blowing machine is one of the most reliable tools for installing any form of insulation. This blog post aims to discuss insulation blowing machines including what they are, how do they work as well as their advantages and top applications.

What is an Insulation Blowing Machine usecs

A machine that injects blown-in or loose-fill insulation materials into wall cavities, attics and some other areas is called the Insulation Blowing Machine! These machines blow insulation materials, including cellulose, fiberglass or mineral wool as combination of air pressure and mechanical agitation to the designated areas making sure it is distributed evenly throughout.

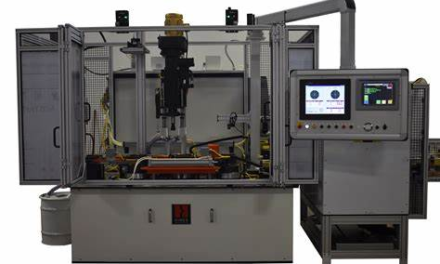

Insulation Blowing Machines Key Features

-

Powerful Air Blowers:

Insulation blowing machines have heavy-duty air blowers that deliver the requisite airflow for transporting and spreading insulation material efficiently.

-

Material Feed System:

The machines come with a feed system that conveys the insulation material from the hopper to the blower. This reduces blockage of material flow.

-

Adjustable Settings:

– Most models offer adjustable airflow and material density settings, providing operators the ability to tailor their application by insulation type and specific job requirements.

-

Hopper Capacity:

Hopper: The size of the hopper that holds material in place and can be continuous or intermittent depending on what needs to go into your machine; larger hoppers mean you don’t have to refill as often.

-

Durable Construction:

Insulation blowing machines are constructed with tough materials and meant to be easily portable.

-

Flexibility:

Residential and commercial machines-Some of these machines also have features that adapt to a range of insulation materials and application techniques.

Benefits of an Insulation Blowing Machine

-

Efficiency:

Insulation blowing machines reduce the time it takes to install insulation by a significant margin compared to manual methods. Fast and uniform application allows for a saving on time and labur costs.

-

Consistent Coverage:

— The machine controls the air flow and density of material for a perfectly even coverage without patches or voids.

-

Better Thermal insulation

Improved Thermal Performance: Insulation when installed properly acts as an ideal thermal performance attribute ensuring the consistent temperature all around and reducing energy consumption.

-

Reduced

Waste:

– Wind-up machines cut waste since they blow insulation directly to the desired areas saving sizeable material.

-

Versatility:

These machines are versatile and can get the project done with various insulation materials like cellulose, fiberglass and mineral wool.

Applications Insulation Blowing Machines

-

Residential Insulation:

Best suited for use in attics, wall cavities and floors of residential structures. They increase the energy efficiency of your home and improve indoor comfort.

-

Commercial Buildings:

Commercial Buildings where Large areas such as ceiling deck are insulated to meet the required energy codes and standards quickly.

-

Industrial Facilities:

Industrial use – used for insulating large structures, machinery and equipment in industrial applications to protect against heat loss or fire.

-

Renovation Projects:

Insulation blowing machines: Insulating a construction after its built is done in such scenarios where the walls or ceilings of an existing building are necessary to be retrofitted with insulation.

Choosing the Right Insulation Blowing Machine

If you focus on an insulation blowing machine, the following are some of that factor.

– Type of Insulation:

– Make sure it is compatible with the insulation material that you intend to use.

– Project Size:

Select a machine that has a hopper size and airflow capacity to meet the requirements of your project.

– Portability:

– If mobility matters to you, find units that are big on lightness and have some sturdy wheels for better manoeuvrability.

– Ease of Use:

Choose models that come with easy-to-understand controls and functions which make operating and maintaining a lot easier.

Conclusion

For efficient and effective insulation installations, you can never go wrong with using an Insulation Blowing Machine. They upgrade energy efficiency, comfort and cost effectiveness in many places due to their ability to quickly encapsulate insulation materials. Choosing the right machine can deliver peak insulation performance and help to provide greater efficiency in your home environment with low energy costs. No matter if it is a residential or commercial installation, you are looking to work on with an insulation blowing machine installed at your workstation; the results will be wonderfully long-lasting.