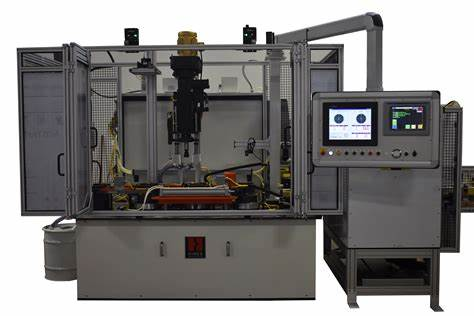

Cincinnati Automatic Balancing Machine This cutting edge equipment is designed to do just that, it provides precision and balance or rotating components essential for a variety of industrial industries. From car parts to industrial machinery, this machine is essential for maintaining the quality and performance of components.

Here Is Video Overview of Cincinnati Automatic Balancing Machine

One: Cincinnati Automatic Balancing Machine – This machine is engineered to measure and correct imbalances in rotating parts. Vibration, noise and wear can all be exaggerated by imbalances causing earlier than scheduled breakdown of machinery or equipment. This involves sensing where the mass is distributed within a part and compensating it to spin easily.

Key Features

-

High Precision Balancing:

It balances with a precision that can detect and correct even the slightest imbalances. This exactness is vital in applications where tiny tolerances make a big difference to performance.

-

Versatility:

Providing flexibility to handle a variety of components, the machine is available in different sizes and shapes which makes it useful for multiple industries like automotive aerospace, manufacturing etc.

-

Automated Operation:

It has automated functions for easier balancing. This way the necessity for manual intervention is minimal which in turn raises efficiency by reducing error cases.

-

Advanced Sensors and Diagnostics

Advanced sensors of the machine help in identifying imbalances to provide a proper diagnostic. That way technicians are able to make recommendations of changes needed.

-

User-Friendly Interface:

The machine features an intuitive user interface that makes for easy operation. It can take input operations from the operators and observe processes to make adjustments.

-

Data Collection and Analysis:

It is capturing during the balancing process that detailed data are being collected by this machine to use and report them. This allows for performance tracking over time, to identify trends or common issues.

Applications

The Cincinnati Automatic Balancing Machine is in use across industries to guarantee the durability and service life of rotating pieces. Key applications include:

Automotive – balancing engine components, drive shafts and brake rotors improve vehicle performance and safety.

Aerospace: Balancing of Jet Engine parts, Propellers for optimized performance/fuel efficiency

Manufacturing: Vibration and wear in industrial machinery components are reduced by balancing, which extends the service time of equipment.

Power Generation – Efficient operation of turbines and generators, maintenance minimization

Benefits

-

Improved

Performance:

Balanced parts allow smoother running – less noise, less vibration = more power.

-

Increased Longevity:

Wear and tear is minimized when components are balanced, thus diminishing regularity of component replacements or maintenance.

-

Enhanced Safety:

Parts are then balanced ensuring safety operation of machinery, decreasing cost in failure and accidents.

-

Cost Efficiency:

Balance investments reduce long-term maintenance costs by lowering downtime and maintaining component life

Conclusion

For this purpose, industries must have access to equipment like the Cincinnati Automatic Balancing Machine It adds richness to the capital of any business – it modernises internal systems, raises everyday standards across all lines and optimizes performance operationally. This machine was important in almost all automotive, aerospace and industrial applications to operate critical machinery smoothly and safely.

![compressor machine: Types, Uses & Benefits [Ultimate Guide]](https://techyhealthcare.com/wp-content/uploads/2024/07/Designer-2024-07-10T163722.062-440x264.png)