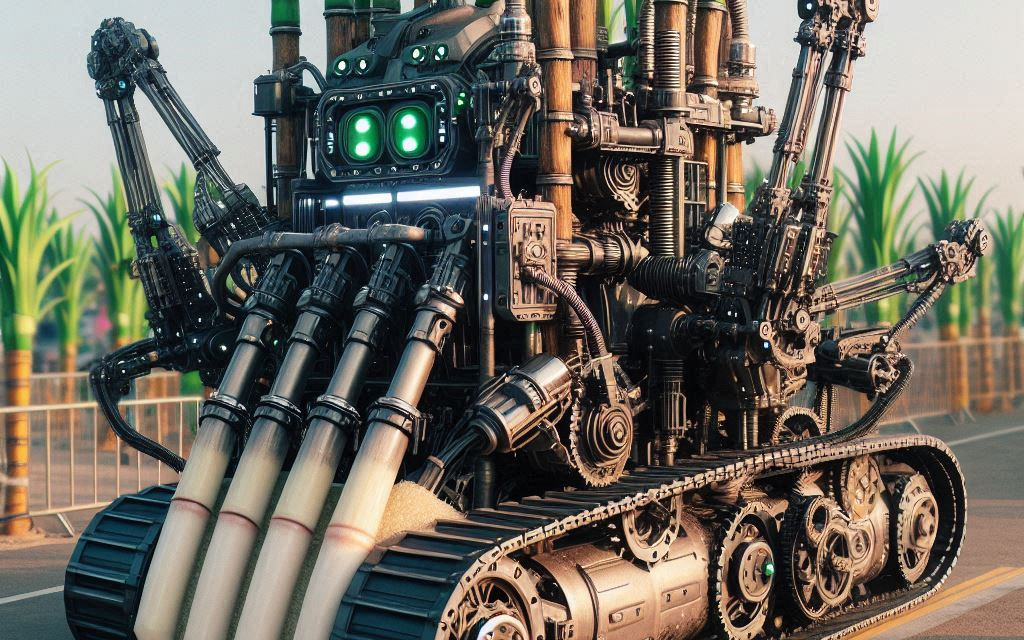

sugar cane machine – Innovation in the manner of extracting juice from sugar cane changed at some point, with sugar cane machines becoming more efficient and hygienic. These are indispensable machines from tiny street vendors of sugar cane juice to huge industrial operations that process sugarcane and produce a plethora of products. Let us explore the world of sugar cane machines, from their types to benefits, application and features that make you decide on these factors when buying one for your work.

What is a Sugar Cane Machine?

Sugar cane machine – Sugar cane juicer – Sugarcane extractor is used to extract juice from sugar canes. It usually comprises rollers or gears to crush the cane and extract its juice, which is later filtered out. They are available in different sizes and capacities for various levels of production.

Types of Sugar Cane Machines

Manual Sugar Cane Machines:

Manual sugar cane machines are suitable for mobile vendors or small-scale operations gated by man only. There is nice and small, simple little machines, no electricity needed just perfect for an efficient way to grind up any truants!

Electric Sugar Cane Machines:

Electric sugar cane machines are motorized and automate the process of crushing. High-speed automatic machines are suitable for medium to large-scale operations as they are much faster and efficient than manual ones. Countertop unit for smaller businesses to industrial-grade machines of all sizes.

Sugar Cane Juice Machines (Hydraulic) :

Hydraulic: the hydraulic sugar cane machines extract a lot of juice by crushing the canes under high pressure. It is the machines of choice for commercial and industrial settings where they can produce large quantities in a shorter period.

Commercial Sugar Cane Machines:

The industrial sugar cane machines are used by large production company, usually in the immense quick support of lucrative enterprises like mills plants. Large volumes of cane can be processed to yield a considerable amount of juice that is then refined into sugar or other products.

The Advantages of Sugar Cane Machines

Efficiency:

Sugarcane machines allow up to nearly 100% efficiency of extracting juice over the traditional manual method. Electric and hydraulic machines are particularly useful for processing large volumes of cane, easily consuming the raw material.

Hygiene:

Cleanliness Easy to clean and maintain cleaned manually prevents mold, dust from adhering making the juice hygienic for humans’ health. The most common approach to avoid contamination is by using stainless steel components and food-grade materials. Counter slots: Stainless Steel & Kitchen Knife Set Photo source Amazon

Consistency:

Perfectly consistent juices with a sugar cane machine Because it’s automated the crushing is processed the same for each cane that gets crushed, leading a consistent product as an outcome.

Versatility:

These devices have potential much beyond juice: this is a sugar cane machine that you can use to produce also molasses and rum. This versatility has the ability to provide an invaluable tool for businesses aiming to expand their product ranges.

Cost-Effective:

Instead of hiring manual laborers to squeeze the juice, a sugar cane machine will be extremely cost effective, and you can save tons on this because it reduces your costs for labour in addition increasing effectiveness up-time. This is particularly true for sugar mills that process extensive volumes of cane.

Uses of Sugar Cane Machines

Street Vendors:

Sugarcane juice is a well-known street beverage in most of the countries. Street vendors in many countries have a small sugar cane machine using it to provide fresh, healthy juice to patrons without understanding how this and other artifact changes their life.

Restaurants and Cafes:

Sugar cane juice is fast becoming the beverage of choice in various restaurants and cafes as a natural thirst-quencher. Countertop electric machines can also be used by establishments to serve fresh juice to their visitors.

Juice Bars:

Sugar cane machines, which specialize in fresh juice and all natural products, are mainly used for unique juice blends by Juice bars. Sugar cane juice is OK for the flavour and nicotinic of fruit/vegetable juice signifying.

Sugar Mills:

For example, in the production of sugar on an industrial scale sugar needs to be squeezed out from cane with the help of special machines developed specifically for this purpose. They are an essential part of the sugar production process, as their performance can greatly affect overall efficiency.

Distilleries:

cane sugar juice, which comprises the basic material that goes into rum and some other spirits; Sugar cane machines break down the sugar into juice, which can be fermented and distilled to make alcohol.

Things to Keep in Mind While Choosing a Sugar Cane Machine

Capacity:

The capacity of a sugar cane machine is the quantity that it can process within a certain amount of time. Assess how much sugarcane will be processed – and the larger production machine relevant to you

Power Source:

Based on what you are going to do and also the availability of power, decide if it is a manual or electric driven machine (power source would be transmitted through hydraulic) Electric and hydraulic devices are efficient but rely upon the availability of electrical power.

Durability:

Stainless steel is ideal as this material will last forever. This will ensure that the machines are durable and have a longer lifespan, meaning less money is spent fixing them over time.

Ease of Use:

Machine operation & re-review machine operating machines. get Column Index machines. filter indices Time to inspect and time per clean in daily operation of straightforward controllers, lots quite under the within-out symbol.

Safety Features:

Ensure that the machine is equipped with enough safety features like protective covers, an emergency stop button and a non-slip base. This way they can avoid accidents and improve safe operation.

Cost:

Drive For the Best Price -Match your budget and requirement with the cost of different machines. More expensive machines may warrant a higher initial expense, but ultimately allow for greater efficiency and longevity which will save money in the long run.

Conclusion

Sugar cane machines changed the way sugar cane juicing was done. And regardless, if you are smaller street vendor or largescale industrial producer we have a juice machine for every needs. These machines have countless advantages such as high productivity, better sanitation conditions and also ensure product uniformity. Buying the best sugar cane machine in support of your planned activities can facilitate you to enhance productivity and meet business aims weighing up closeness, influence etc. Sugar cane machines and find sweet innovation in your sugar cane juice production