Jack machine is the equipment that is required during lifting of heavy loads, maintenance tasks or even in making a safe structure while executing construction projects. Because they can easily lift and hold large amounts of weight, this makes them invaluable in numerous industries Applications for these adaptable tools include not only the auto repair sector but also construction or anywhere heavy loads are needing to be moved. In this blog post, we will cover the basics of jack machines: what they are used for and their types as well as some of the advantages you would get from a few considerations on choosing an appropriate option suitable to your need.

What is a Jack Machine?

Jack Machine A jack machine, also known as a jack, is primarily used to lift heavy loads) & A screw thread or hydraulic mechanism is used for the force, which can be used to lift a load (raise), lower a load/lower it away safely (hold) and live. Jack machines are used in a variety of applications and come indifferent designs and capacity.

Applications of Jack Machines

Automotive Repair:

Automotive repair: One of the most basic uses of jack machines is in specialist car garages. Hydraulic floor jacks are used by mechanics to elevate a vehicle off of the ground so that they can work under, or on them easier for things like performing tire changes, as well as inspecting undercarriages and conducting repairs.

Construction:

Jack machines are used for lifting and placement of construction materials such as steel beams, concrete blocks etc. They are also used to prop up structures temporarily for the construction of repairs.

Industrial Maintenance:

Hydraulic Jack Machines are used in industries to lift heavy machines so that maintenance can be done. This makes it possible to service equipment in a safe and effective manner.

Railroad Maintenance:

Jack machines for lifting and aligning train cars and tracks are employed in the railway industry. It is also used to maintain rail systems neatly.

Heavy Equipment Handling:

In different industries such as mining, manufacturing and logistics these Jack machines are used for lifting of heavy equipment Cumbersome loads can be lifted with the help these industrial equipment’s. This makes the installation, maintenance and moving of heavy machineries easy.

Types of Jack Machines

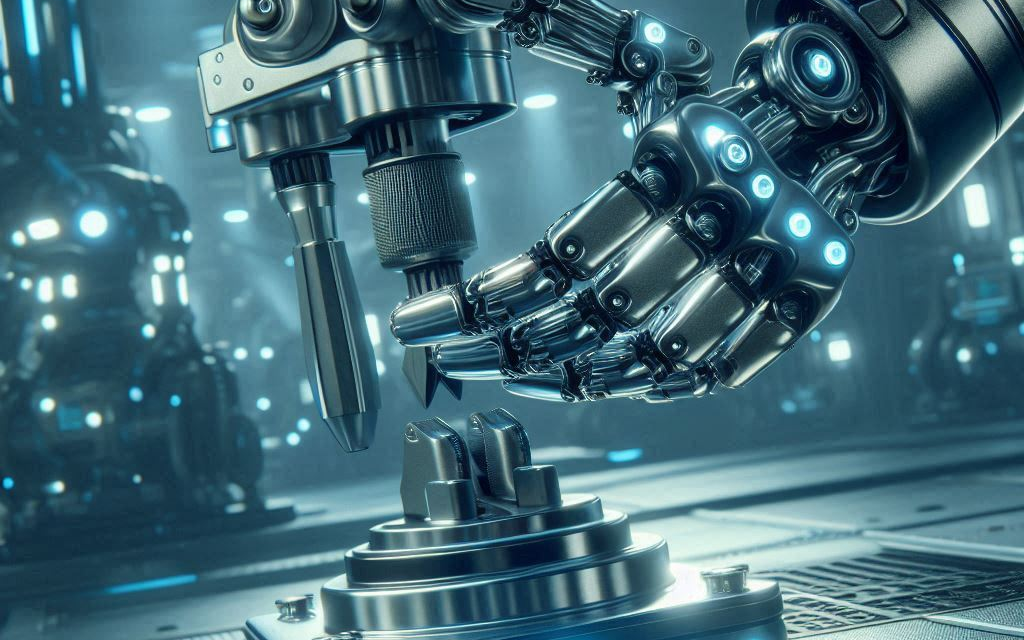

Hydraulic Jacks:

Hydraulic jacks work by means of fluid pressure, making it easier to lift large loads. They are recognized for their weight carrying capacity and easy handling. There are different types of hydraulic jacks that one can buy, some common type is floor jack, bottle jack and trolley jak. Automotive repair & industrial maintenance, countless applications use these jacks.

Mechanical Jacks:

Mechanical jack uses the screw thread or a ratchet mechanism which lifts heavy loads. These are Long lasting and reliable community. Many modern garage tools are the descendants of once manual mechanical jacks, like scissor jacks, screw jacks and ratchet (or hydraulic) jacks. These jacks are primarily used in construction and railway maintenance.

Pneumatic Jacks:

Blowpipe Jacks – blowpipe jacks are air-powered raising systems that utilize pressed gas to increase lots. However, they are very fast and high in efficiency. There are also some instances when these jacks can be used in heavy equipment handling and industrial settings that need quick lifting up.

Electric Jacks:

An electric jack lifts loads with its own electric motor. The sleep pods are renown for readily available to use. The Rapid Action Jack is a common type of jack which has different applications, but often used in the automotive repair and maintenance lines where they want to be able quickly lift something.

Advantages of Jack Machines

Versatility:

Jack machines are useful in so many different areas from automated repair to operating heavy equipment Their wide use makes them indispensable in numerous industries.

Ease of Use:

Easy to Use: Jack machines are created in such a way that will give the best output even with little effort you can raise heavy objects. In particular, hydraulic and electric jacks will not have any effort to lift up.

Safety:

Lifting and holding heavy loads under a vehicle should not be done with some regular jack but with the one lifting machine (jack) by looking at this because that will guarantee your security too. Some heavy-duty jack machines have safety features and accessories, such as overload protections or mechanical locks.

Efficiency:

Jack machines make it easy to lift heavy loads, which can be very useful in different types of tasks saving time and work. This is especially advantageous in industrial and construction environment where time matters.

Durability:

The Jack machines are made of the high-level material in difficult condition and have an operating limit to provide maximum workload. The best jacks on the market are constructed from strong materials with built-in durability to last a long-lasting service life.

Factors to be Considered in Choosing a Jack Machine

Load Capacity:

A jack machine has a load capacity, and this is one of the most important things you need to take into account. Make sure the jack can operate with a load of your design weight. Overloading a jack can cause the equipment to fail and create dangerous situations.

Lifting Height:

Jack machine maximum lifting height. Confirm that the lift height will work for your application. Jack 1Correct, as bottle jacks have more lift than other types of jack.

Type of Jack:

Grab the best jack suited for you. Most of the time Hydraulic jacks are used for heavy lifting and mechanical jack is tough. Quick and easy buckle jacks – Pneumatic vs. Electric

Safety Features:

Choose a jack machine with safety attributes including overload protection, lockouts and solid footing bases. These are what make it possible to operate the device safely and without any accidents

Portability:

Jack Machine Portability – Think Of Una Pila Choose a lightweight model if you will be moving the jack around frequently. Others have wheels or handles for better reach.

Maintenance:

For the long lasting and excellent performance of jack machines, you need to make sure that they are regularly serviced. Select a jack for which maintenance is straightforward and for which clear guidelines on regular servicing are provided.

Conclusion

The necessity of the jack to lift heavy objects in a variety of industries means it is an essential machine, making this features valuable while using. Learn about the different types of jack machines, their uses and benefits to help you decide which type of jack is best for you. In the world of automotive repair, construction or industrial maintenance (just to name a few examples), having a trustworthy machine that can lift heavy loads efficiently and provide both safety for your employees as well as relief on their muscles is an often unsung hero(asset) when it comes down to maximizing productivity.